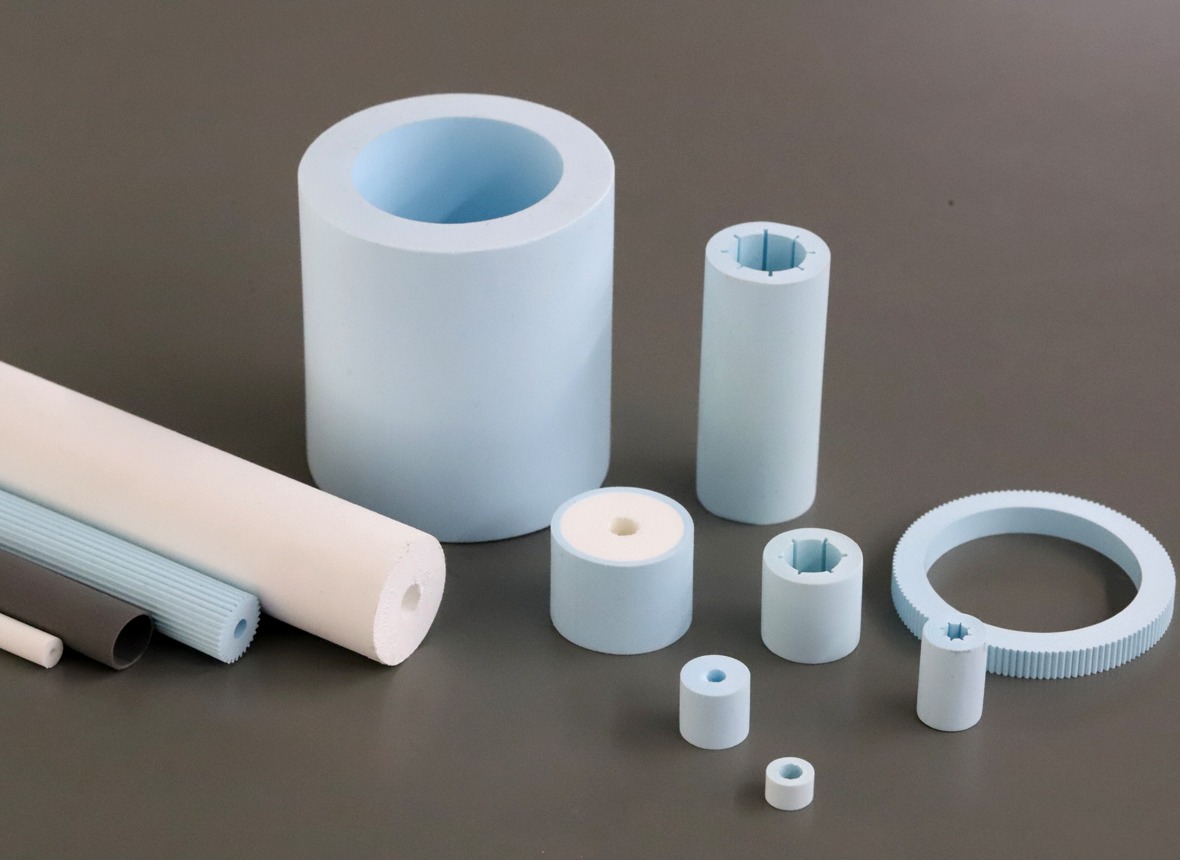

Yamahachi Porous Roller is a roll-shaped porous material with great features such as flexibility, permeability, venting, collectability, hydrophobic, and low dust generation (lint-free) which can be produced using a base material with Polyethlene (PE).

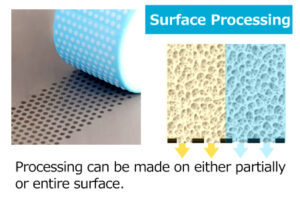

This material absorbs liquids such as oil and ink, and is effective especially for liquid application. We can provide custom-made products not only simple roller shapes but also special shapes such as gear shapes. Option processing or adjustment such as surface processing (closing entire/partly pores of surface), and/or the physical property adjustments required are also available.

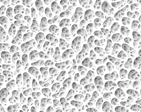

What is open-cell porous plastic?

Basic properties

| Material: LDPE |

Pore size(μm):5 – 30μm (random) |

| Heat resistance temperature(℃):50-100℃ |

Porosity(%):60 – 80% |

| Flexibility |

Flexible and does not damage the surface or workpiece |

| Permeability |

Penetrate into oil and ink |

| Ventilation |

Passes air or gas |

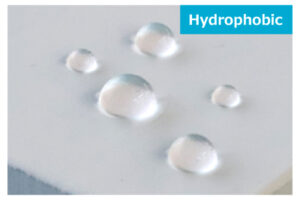

| Hydrophobic |

This product has weak interaction with water and does not absorb water or moisture |

| Durability |

Polyethylene-based material , highly durable |

| Lint-free |

No fiber material used. Low dust generation material that does not cause the base material to fall off. |

| Chemical resistance |

Highly resistant to acids and alkalis, and relatively resistant to oils and organic solvents. |

| Dimension (mm) |

Outer diameter φ6 ~ φ50mm x Inner diameter φ2.5mm ~ x Length ~100mm |

Options

| Material:HDPE、EVA、PP |

Adjustment of hardness |

Adjustment of porosity |

Hydrophilization |

| Special shape (gear) |

Double-layer |

Surface processing (partly) |

Surface processing (entirely) |

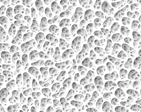

Kind of Porous structures

We design the porous structure according to the customer’s physical properties and applications.

| Kind |

Overview |

| Standard structure |

Continuous porous structure connected in a three-dimensional network. The walls between the pores are open, providing vent and liquid permeability. |

| Double-layer |

Double layers of porous material with different pore sizes formed into a roller shape. The inner layer has a high porosity, and the surface layer has fine and dense pores. |

| Surface processing (partly) |

Partially processed porous surface in roll shape. Air/gass and liquid do not pass through the processed parts, but the unprocessed parts maintain their porous function with vent and peamiability. Detailed designs such as dot patterns can be processed on the surface, and functions such as applying a small amount of oil can also be added. |

| Surface processing (entirely) |

The entire surface is processed to seal the entire pores on the surface. The inner layer retains its porous function with features of vent and peamiability, and the processed surface layer does not allow ventilation or liquid to pass through. |

|

|

|

|

|

|

|

|

| Standard structure |

Double-layer |

Surface processing (partly) |

Surface processing (entirely) |

Applications

| Lubricant applicator roller |

Ink roller |

Absorbent material |

Absorbent roller material with oil and ink |

Marking materials |

This product is basically custom order and/or development. Based on the application and the customer’s required physical properties and specifications, we will conduct trials and production that bring the best porous material to the customer.

| Need any help ? Please contact us ! |

If you have any questions or would like to receive more detailed information or samples, please complete “contact form” and a company representative will contact you.