Features of Yamahachi Porous Plastic

Features

Features of Yamahachi Porous

Yamahachi Porous Plastic has great features for your innovative products

Functional porous plastic with opening pores

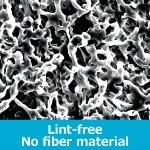

Our open cell porous plastic has an abundance of continuous pores in its structure. It is made from polyethylene (PE) with 60-80% of the total material volume of opening micropores in its structure, characterised by flexibility, absorption and chemical resistance. These unique properties make it possible to meet many application needs in a wide range of fields.

We mainly produce our porous plastics by injection moulding and extrusion. However, depending on the shape and customer application requirements, we can also add secondary process such as grinding or other special processing after moulding.

If necessary, our technical engineers can offer additional options according to your needs for your product. Let us challenge you with a new innovation!

Standard Features

| Material :LDPE | Pore size:5 – 30 μm | Porosity:60 – 80% | Heat resistance: 50-80°C |

| Flexibility | Flexible and does not damage the surface of workpiece or object |

| Absorption | Easy to penetrate liquids such as oil and ink |

| Venting | Passes air or gas |

| Hydrophobic | Having weak interaction with water, so not absorbing water or moisture |

| Shape range | Standard shapes such as sheets, rolls and tubes by extrusion, and also complex 3D shapes by injection molding |

| Durability | Highly durable (PE) |

| Lint-free | No fiber is used, not easy to create a dust or a lint. |

| Chemical resistance | Highly resistant to acids and alkalis, and relatively resistant to oils and organic solvents |

|  |  |  |

Options

| Material | HDPE, EVA, PP |

| Hardness adjustment | Can be customized |

| Porosity | Can be adjusted |

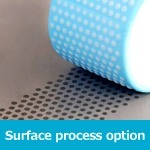

| Closing pores on surface | Processing to close the pores on the surface (surface process option). Surface processing with pattern such as small dot pattern can be made. |

| Assembling | Assembling into other parts such as fiber shafts and molding parts |

| Grinding | Grinding the nib porous parts, etc. |

| Two-layered porous | Two-layer structure with different pore sizes |

| Hydrophilization | Change from hydrophobic to hydrophilic |

|  |  |  |

What is Open cell porous plastic ?

Main solutions

| Application | Reservoir | Venting |

| Absorption | Printing | Rust prevention effect due to hydrophobicity |

Click here for Functions and Applications

Chemical and solvent resistant

Reference data for chemical and solvent resistance

Infiltrated in a constant temperature chamber at 23°C and measured after a certain time without swelling ;

| concentrated hydrochloric acid | Hydrogen peroxide water | Ethylene glycol |

| Nitric acid (concentration 30) | Ammonia water | Polyethylene glycol |

| Sodium hypochlorite | Glycerine | Formic acid |

| Ethanol | Methanol | IPA |

| Acetone | Sodium chloride (aqueous solution) | Surfactants (anionic) |

| Surfactants (nonionic) | Oxalic acid (saturated aqueous solution) | Butanol |

| Need any help ? Please contact us ! |

If you have any questions or would like to receive more detailed information or samples on Yamahachi Chemical, please complete a “contact form” and a company representative will contact you.