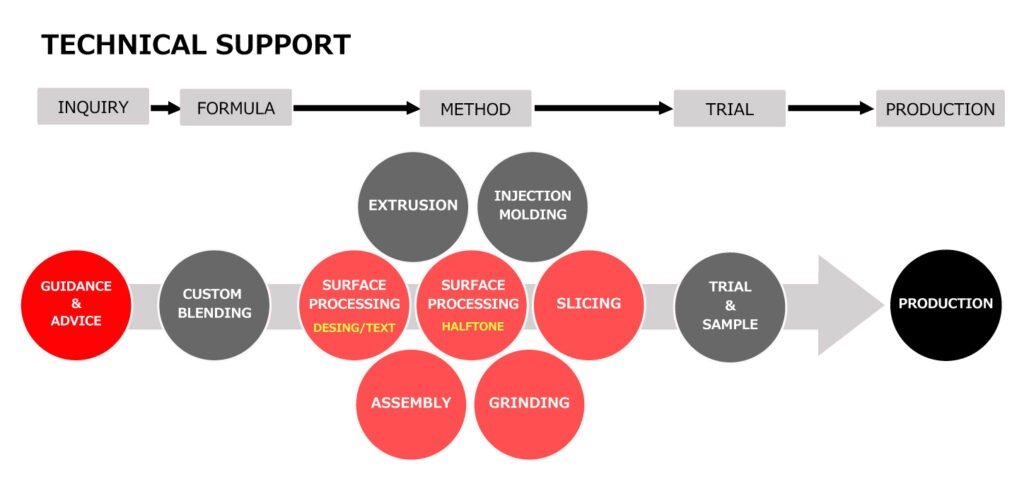

Technical support

Custom porous plastic

Driving customers successes

for innovative development with multiple technologies

For customer’s innovative development

Our primary goal is to being a valuable partner with our customers to bring their innovation ideas into real. Yamahachi has technical support teams are composed of engineers and skilled production team who have expertise covering blending materials, components design, molding and secondary processes of porous foams. They are qualified to assist in your innovative projects by solving problems and delivering the best porous plastic solutions.

What is Open cell porous plastic ?

Blending

■ Custom Blending ■

Selecting raw materials and the best combination of blending. If necessary, basic research and trial will be carried out.

Standard polymer : LDPE

Possible polymer:HDPE, EVA、PP

Molding

■ Extrusion molding(simple shapes) ■

Extrusion molding produces a long continuous shape by extruding plastic material through heated mold. It is suitable for molding items with the same cross-sectional shape.

Shapes:sheets、rodes、pipes

Applications:Flash foam (stamp material), Rolling stamp parts, Special oil applicators

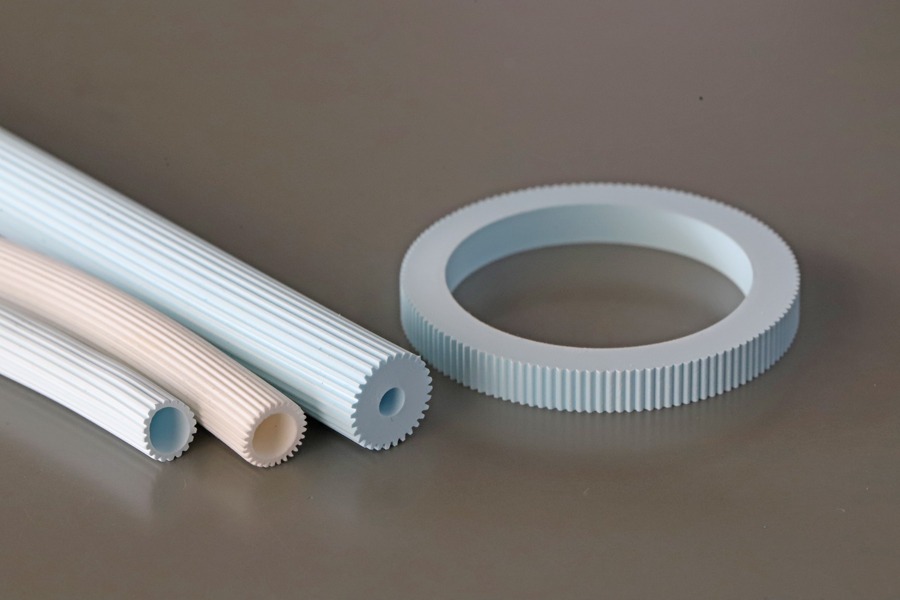

■ Extrusion molding (complex shapes) ■

Sheets and/or pipes with special surface geometries or continuous inner hollows can be produced also by extruder using special dies/molds.

Shapes:sheets、rodes、pipes with special surface geometries or inner hollows

Applications:Small amount oil applicator, Special absorbent

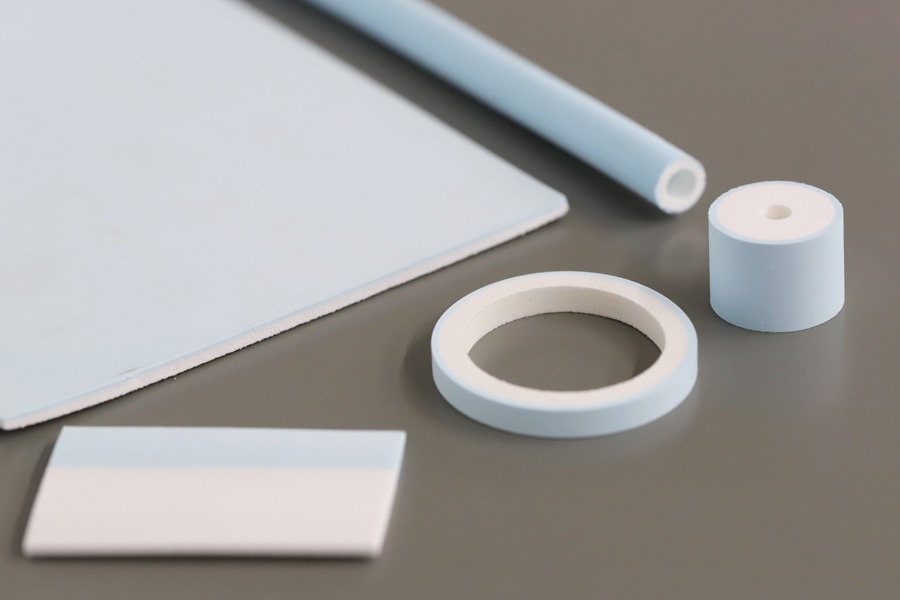

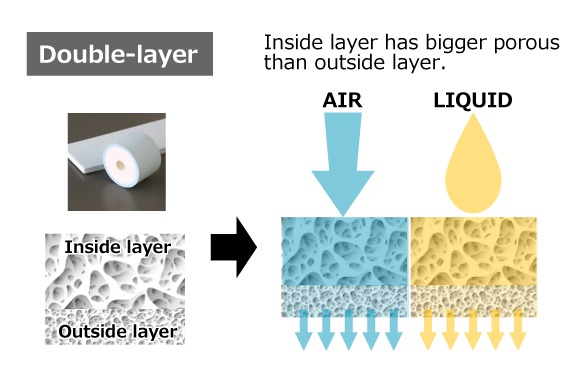

■ Extrusion molding (double layer) ■

Double-layer extrusion is an advanced manufacturing method that involves the simultaneous extrusion of porous materials with two different sized pores. Unique properties can be achieved, such as larger pores in the inner layer to form a reservoir layer for solutions or special filter functions.

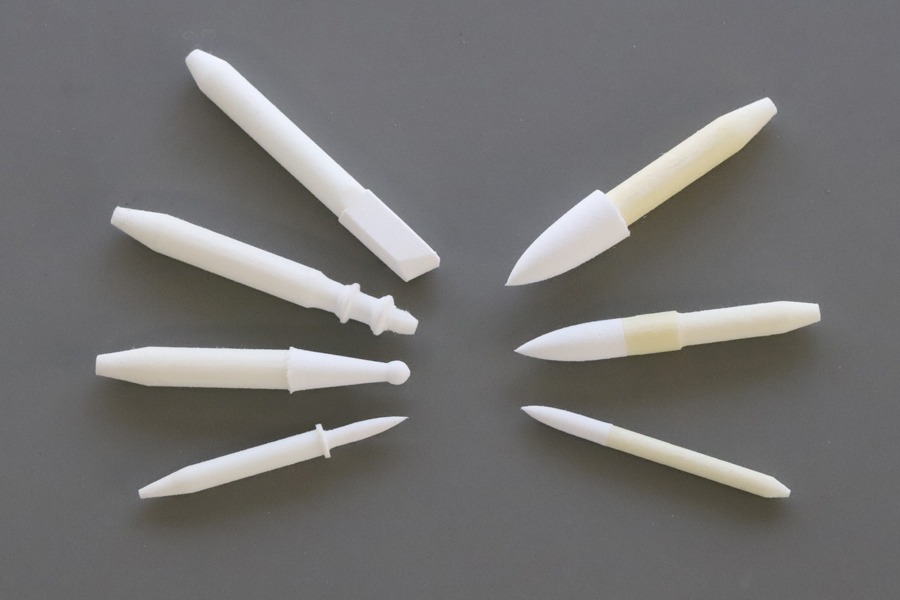

■ Injection molding ■

Injection molding is a method whereby heated, molten plastic material is injected into a mold, cooled and solidified, and molded by injection molding machine(s). It is suitable for the mass production of complex, precisely shaped products.

Shapes:various shapes including complex shapes

Applications : Porous nibs for markers, Porous components of applicators, Marking devices and Absorbents

Secondary processes / optional process

■ Assembly ■

Molded porous plastics can be assembled to different component for example a fiber ink feeder to provide strong capillary force and ink flow.

Shapes:Various shapes including complex shapes

Applications: Eyeliner tips, Porous nibs for markers, Porous components of applicators, Marking devices and Absorbents

■ Grinding ■

Grinding is a secondary process by grinding machine to grind the surface of the porous plastic to finish its shape.

Shapes:various shapes including including complex shapes

Applications : Eyeliner tips, Porous nibs for markers, Porous components of applicators, Marking devices and Absorbents

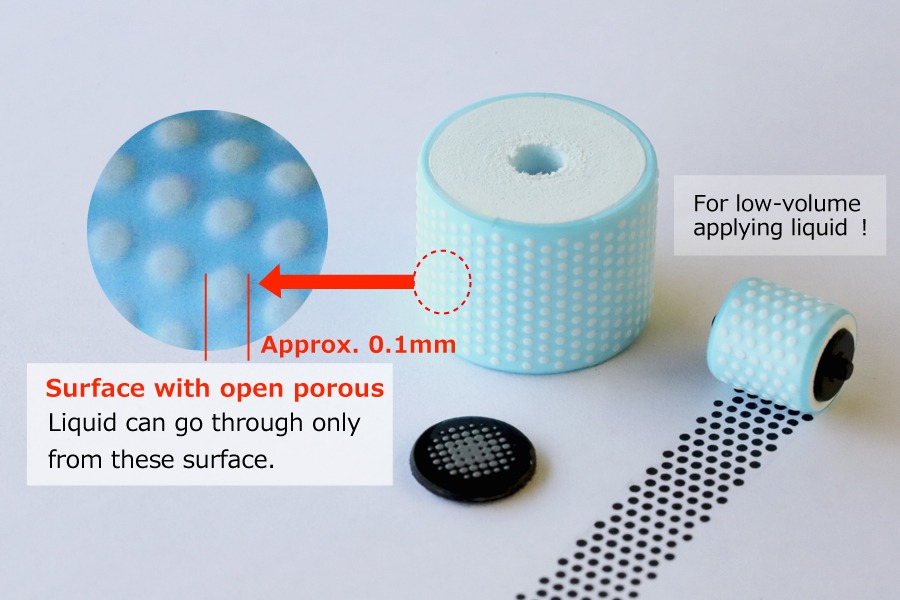

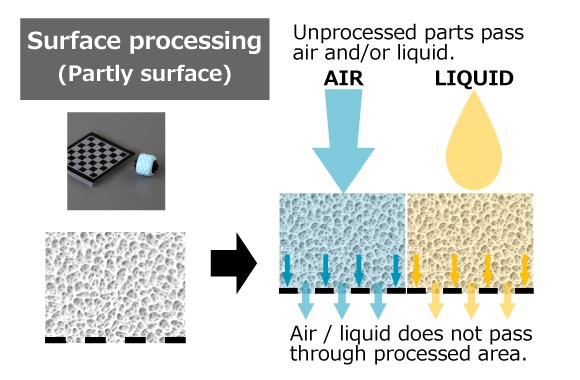

■ Surface processing for low volume applying and small venting ■

This processing method is for sealing pores with a fine pattern on requested part of the surface of porous foams. Size approx. 0.1 mm of dots can be processed. The sealed parts will be blocked to prevent the passage of liquid to give a function of low volume of liquid applying or air venting.

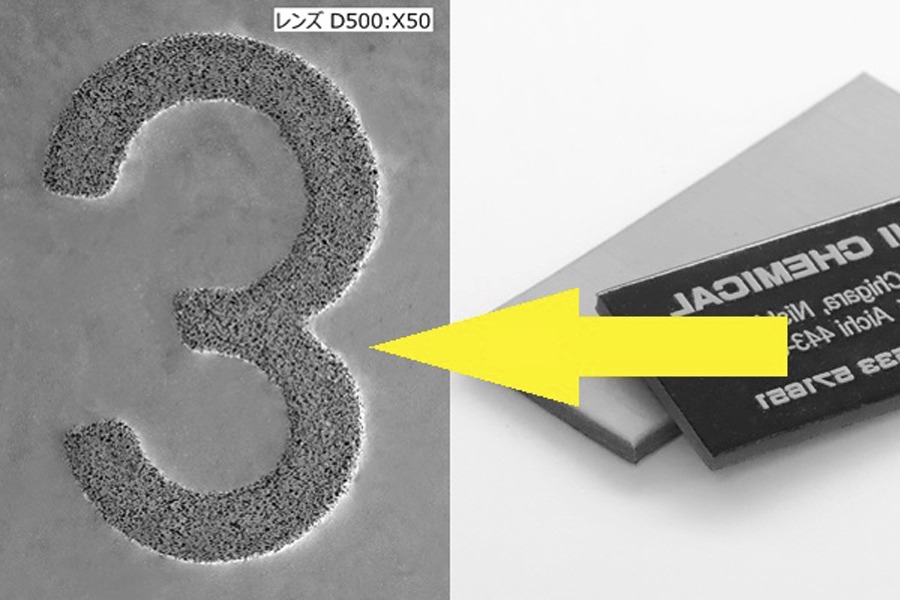

■ Surface processing (text/design) ■

This processing method is for sealing designs and/or texts on required surface of porous plastic. The pores in the processed area will be sealed, leaving the inner layer with its continuous porous structure. No liquid/ink can go flow through the sealed areas on the surface.

Applications:Stamp material, Porous components of marking device

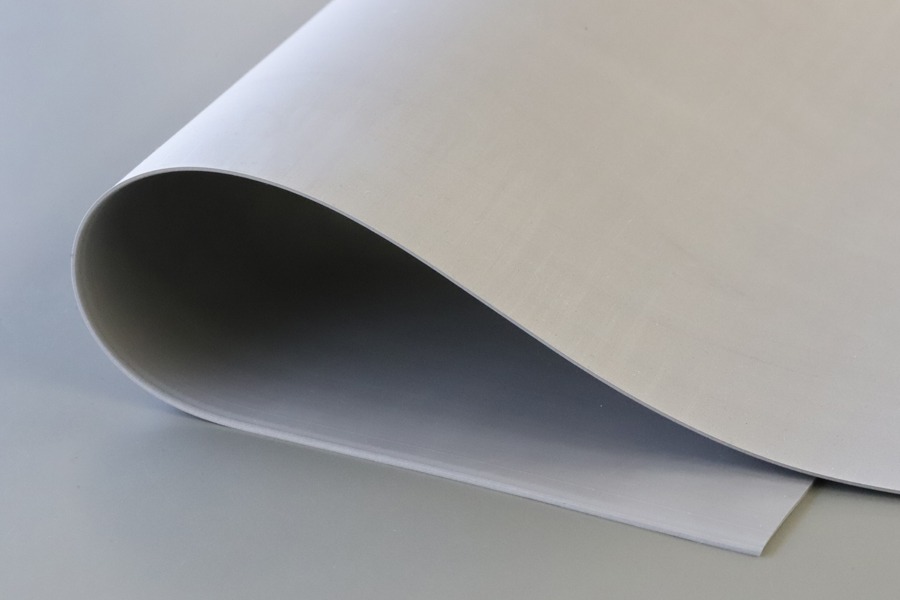

■ Slicing ■

This processing method is for slicing porous plastic sheet using a high-precision slicing machine.

Shapes:Sheet

Applications:Porous plastic sheet

| Need any help ? Please contact us ! |

If you have any questions or would like to receive more detailed information or samples on Yamahachi Chemical, please complete a “contact form” and a company representative will contact you.